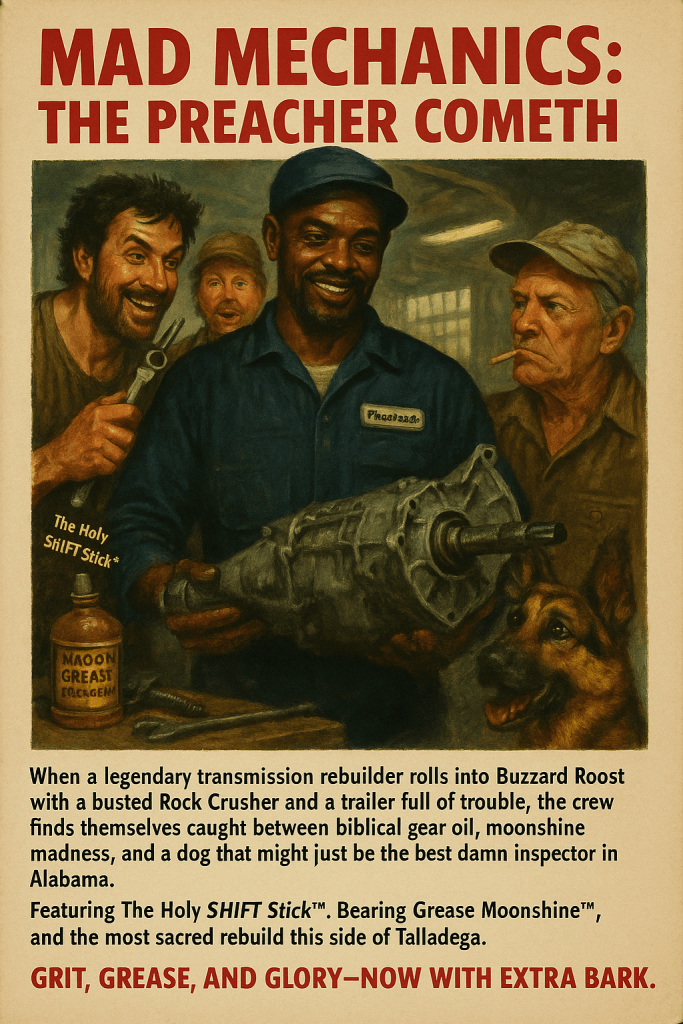

Episode 4: Mad Mechanics: The Preacher Cometh

Written by: Emmitt Owens

*As narrated by: Waylon*

Waylon, Intro: “Well now, folks, settle in for a tale about the day the Mad Mechanics crew met their match in the form of a man who could make a busted transmission sing hymns and purr like a contented church cat. This here story takes place on one of them Alabama mornings when the humidity was thicker than Gutglor’s moonshine and the temperature was climbing faster than a cat up a curtain.”

Chester was knee-deep in the engine bay of a 1971 Pontiac LaMans that belonged to Billy Ray Hutchins, trying to figure out why it was making a noise that sounded like a coffee grinder full of marbles. From the old radio perched on a stack of used air filters, Chris Stapleton was growling out “Midnight Train to Memphis,” which seemed mighty appropriate for what was about to roll into their lives.

“Gary!” Chester hollered, his voice echoing off the tin roof. “This here Pontiac’s got more problems than a preacher’s kid on Saturday night!”

Gary looked up from the carburetor he was rebuilding, his non-filter’d cigarette dangling from his lip like it was part of his anatomy. “What’s she doing now?”

“Making noises that ain’t in any service manual I ever read,” Chester replied, wiping his hands on a rag that had seen more action than a honky-tonk dance floor. “Sounds like somebody’s torturing a bag of cats in the transmission.”

About that time, the rumble of a diesel engine announced the arrival of what would either be their salvation or their doom. A pristine 1970 Chevelle SS pulled into the shop yard, its Cowl Induction hood gleaming in the morning sun like automotive jewelry. But the real surprise was what was being towed behind it – a trailer carrying what appeared to be the corpse of another Chevelle, this one looking like it had been through more battles than a Civil War cannon.

The driver climbed out of the pristine Chevelle, and the boys could immediately tell they were dealing with someone who took his automobiles seriously. He was a tall, lean fellow wearing clean coveralls with “Prechardt Transmissions” embroidered on the pocket, and he moved with the careful precision of a man who’d spent his life working on things that could bite back if you weren’t respectful.

“Afternoon, gentlemen,” the stranger said, tipping his cap. “Name’s Samuel Prechardt, but most folks just call me Preacher. I’m looking for the Mad Mechanics crew – heard y’all might be interested in a challenge.”

Chester and Gary exchanged looks that could’ve communicated entire conversations about the kind of challenges that usually found their way to Mad Mechanics.

“That’d be us,” Chester replied cautiously. “What kind of challenge we talking about?”

Preacher walked over to his trailer and patted the hood of the battle-scarred Chevelle like he was greeting an old friend. “This here’s a 1970 Chevelle SS 454 with a Muncie M22 Rock Crusher 4-speed. Belonged to my uncle, rest his soul. Engine’s been rebuilt, suspension’s solid, but that transmission…” He shook his head like a doctor delivering bad news.

“What’s wrong with it?” the Professor asked, emerging from the back of the shop with his ever-present notebook.

“Everything,” Preacher replied simply. “Input shaft’s broke, main shaft’s bent, half the gears are stripped, and the case has a crack you could stick your finger through. It’s deader than disco.”

Reedus wandered over, wearing a t-shirt that read “I Break Things So You Don’t Have To” and immediately started examining the wounded Chevelle with the intensity of a crime scene investigator.

“Why not just swap in a different transmission?” Reedus asked. “Throw in a Turbo 400 and call it a day?”

Preacher’s expression suggested that Reedus had just suggested painting the Mona Lisa with house paint. “Son, this here’s a numbers-matching Rock Crusher. There’s maybe three hundred of these left in the country, and most of them are sitting in museums or private collections. You don’t just ‘swap’ a Rock Crusher.”

Intermission: “Now folks, let me pause here to tell you that when a man talks about a transmission like it’s a piece of biblical scripture, you’re either dealing with a genuine craftsman or someone who’s spent too much time alone with gear oil – and with Preacher Prechardt, it was definitely the former.”

“So what you need from us?” Chester asked, lighting up another cigarette.

“Well,” Preacher said, pulling out a business card that looked like it had been printed in the 70’s on a pulp book cover, “I heard y’all have a reputation for taking on impossible projects. Problem is, I’m the only man in Colbert County who can rebuild a Rock Crusher proper, but I need space, equipment, and maybe an extra set of skilled hands.”

Gary squinted at the business card. “Prechardt Transmissions – Rebuilding Dreams Since 1963.”

“Started by my daddy,” Preacher explained. “I been working on transmissions since I was little enough to ride in a toolbox. But this Rock Crusher’s gonna need more than just my shop can provide.”

Gutglor appeared from his corner of the shop, carrying a jug of his blueberry moonshine and wearing coveralls that had seen enough automotive action to qualify for veteran’s benefits. “What’s this about needing space?”

“This transmission’s gonna require complete disassembly, case welding, custom machining, and about two weeks of meticulous reconstruction,” Preacher explained. “My shop’s tied up with other work, and honestly, I could use the kind of creative problem-solving y’all are famous for.”

The Professor was already taking notes with the intensity of a man documenting the discovery of fire. “A Muncie M22 Rock Crusher – that’s a close-ratio four-speed with a 2.20 first gear ratio. Extremely rare, designed for high-performance applications.”

“You know your transmissions,” Preacher observed, impressed.

“I know my automotive history,” the Professor replied. “Though I confess my practical experience with manual transmission reconstruction is somewhat limited.”

“That’s where I come in,” Preacher said. “I can teach anybody who’s willing to learn, but this project’s gonna need all the expertise we can muster.”

Chester walked around the wounded Chevelle, studying it like a doctor examining a patient. The car was rough around the edges – paint faded, chrome pitted, interior torn – but underneath the battle scars, you could see the bones of something special.

“What’s your timeline?” Chester asked.

“No real deadline,” Preacher replied. “This is a restoration, not a repair. Want to do it right, not fast.”

“That’s refreshing,” Gary muttered, thinking about all the rush jobs that had come through their shop over the years.

Reedus was already crawling around under the Chevelle, poking and prodding with the enthusiasm of a man who’d just found a new toy. “Boys, this is what I call a real gear-grinding opportunity! We’re gonna shift this project into high gear!”

“Oh Lord,” Gary groaned. “Here we go with the transmission puns.”

“Can’t help it!” Reedus called out from under the car. “This whole project’s got me all revved up! We’re really gonna clutch this restoration!”

Preacher watched this exchange with the bemused expression of a man trying to figure out what he’d gotten himself into.

“Don’t mind Reedus,” Chester explained. “He makes puns about everything. You’ll get used to it.”

“Or go insane trying,” Gary added helpfully.

Gutglor had been examining the Chevelle with professional interest, running his hands along the body panels and peering through the windows. “She’s got good bones,” he announced. “Gonna need bodywork, paint, interior, but the foundation’s solid.”

“That’s the plan,” Preacher agreed. “Complete frame-off restoration. Engine’s already been rebuilt – 454 big block with all the right internals. Just need to get that transmission sorted out.”

The Professor was practically vibrating with academic excitement. “This could be an excellent learning opportunity. I’ve always wanted to study the mechanical principles of manual transmission operation from a hands-on perspective.”

“You mean you want to get your hands dirty,” Chester translated.

“Precisely,” the Professor admitted.

Intermission: “Y’all, I gotta stop right here and say that when a college-educated man gets excited about taking apart a transmission, you’re witnessing either the birth of practical knowledge or the complete breakdown of academic pretension – and today, the Professor shows his interests.”

“Alright, Preacher,” Chester said, extending his hand for a shake. “You got yourself a deal. We’ll clear some space in the shop, and you can set up your transmission surgery station.”

“Appreciate it,” Preacher replied, his handshake firm as a vise grip. “Fair warning though – I’m pretty particular about how I work. This Rock Crusher’s gonna need precision and patience.”

“We got plenty of both,” Chester assured him, though everyone in the shop knew that “precision” and “patience” were not exactly Mad Mechanics’ strongest selling points.

Over the next few days, Preacher set up what he called his “transmission cathedral” in the back corner of the shop. The area was organized with military precision – every tool had its place, every bolt had its container, and every procedure had its proper sequence. It was like watching a master craftsman prepare for surgery.

The radio had switched to playing Muddy Waters’ “Can’t Be Satisfied,” and somehow that old blues seemed to capture the restless energy that was building in the shop as everyone watched Preacher work with surgical precision.

“First rule of transmission work,” Preacher explained to his gathered audience, “is respect. This here Muncie has been shifting gears for over fifty years. She deserves to be treated with dignity.”

He carefully removed the transmission from the Chevelle using a combination of hydraulic jacks, engine hoists, and what appeared to be pure mechanical intuition. The Rock Crusher looked even worse out of the car – case cracked, oil leaking from every seal, and making rattling sounds that suggested expensive internal damage.

“She’s hurt bad,” Preacher observed, setting the transmission on his custom workbench. “But she ain’t dead. Just needs some healing.”

The disassembly process was like watching a mechanical autopsy performed by someone who genuinely cared about the patient. Preacher worked with deliberate precision, explaining each step to his fascinated audience.

“See this input shaft?” he said, holding up a piece of twisted metal. “This is what happens when somebody tries to power-shift without proper clutch technique. Snapped clean through.”

Gary examined the broken shaft with professional interest. “Can you fix it?”

“Can’t fix it,” Preacher replied. “But I can replace it. Got a guy in Detroit who specializes in Muncie parts. Costs more than most people’s car payments, but it’s the only way to do it right.”

The Professor was taking notes with scientific precision, documenting every step of the disassembly process. “The mechanical complexity is fascinating. Each component must work in perfect harmony with the others.”

“That’s exactly right,” Preacher agreed. “One bad part ruins the whole system. That’s why every bolt, every gasket, every bearing gets inspected and replaced if there’s any doubt.”

Reedus was studying the gear arrangement like a man trying to solve a mechanical puzzle. “So this is what makes the magic happen? All these gears working together to transfer power?”

“Power and torque,” Preacher corrected. “The Rock Crusher was designed for high-performance applications – drag racing, road racing, street performance. It’s built to handle serious power.”

Over the following weeks, the Mad Mechanics shop became a combination transmission hospital and automotive university. Preacher taught anyone who wanted to learn, sharing decades of accumulated knowledge about gear ratios, synchronizers, and the subtle art of making metal parts work together in perfect harmony.

Chester learned about input shaft selection and bearing preload. Gary discovered the mysteries of gear timing and synchronizer adjustment. The Professor filled an entire notebook with technical specifications and theoretical calculations. Even Reedus managed to contribute, using his fabrication skills to create custom tools for the rebuild process.

“What I need,” Reedus announced one afternoon, “is something to hold these synchronizer rings in perfect alignment while I install the clutch hub. Something with just the right angle and grip.”

He disappeared into his corner of the shop for about an hour, emerging with what looked like a combination of a dental pick, a small vise grip, and pure mechanical inspiration.

“Behold!” Reedus declared dramatically, holding up his creation. “I call it the Holy Shift Stick! It’s gonna revolutionize transmission work!”

“The Holy what now?” Chester asked, looking up from his carburetor rebuild.

“Holy Shift Stick!” Reedus repeated proudly. “See, it’s got a holy purpose – helping with shifts – and it’s shaped like a stick! Plus, when you use it, you’ll probably say ‘Holy shift, that works good!’”

Gary groaned audibly. “That might be your worst pun yet.”

“I think it’s brilliant,” the Professor observed, examining the tool with scientific interest. “The engineering is actually quite sound.”

Preacher tested the device and had to admit it worked perfectly for holding synchronizer components in place. “Well, I’ll be,” he said, genuinely impressed. “That there’s a handy little tool, regardless of what you call it.”

“See?” Reedus grinned. “The Holy Shift Stick is gonna be legendary! I might even patent it!”

The comedy continued a few days later when Preacher spent a full hour searching for his precision micrometer – the kind that cost more than most people’s monthly rent and was essential for measuring bearing clearances to within thousandths of an inch.

“Has anybody seen my micrometer?” Preacher asked, his usual calm demeanor showing signs of strain. “I set it right here on the workbench not twenty minutes ago.”

The entire crew joined the search, looking under every tool, behind every component, and in every corner of the transmission cathedral. Preacher’s organized workspace was carefully disassembled and reassembled in the quest for the missing precision instrument.

“I swear I didn’t touch it,” Chester said, checking his own toolbox for the third time.

“Maybe it grew legs and walked off,” Gary suggested unhelpfully.

After an hour of increasingly frantic searching, Preacher stood in the middle of his workspace, scratching his head with a look of complete bewilderment.

“I been working with micrometers for thirty years,” he muttered. “Never lost one yet. This is… this is just not like me.”

That’s when his eyes fell on the mason jar sitting on Gutglor’s workbench – the one that had contained the “Smooth Shift” moonshine sample from earlier that morning.

“Gutglor,” Preacher said slowly, “exactly how strong was that shine you gave me to try?”

“Oh, that was just a little taste,” Gutglor replied innocently. “Maybe 120 proof. Nothing serious.”

“120 proof?” Preacher’s eyes widened. “I thought you said it was a ‘light sample’!”

“Well, it was light-colored,” Gutglor grinned.

Preacher stared at the empty jar, then at his meticulously organized workspace, then back at the jar. “I don’t drink when I’m working,” he said slowly. “I got a strict policy about that.”

“You did say you appreciated the gesture,” Gutglor pointed out. “And you did take that sip to be polite.”

“That was supposed to be a polite sip!” Preacher protested. “Not a… a… whatever that was!”

“Found it!” Reedus called out from across the shop. “Your micrometer’s in the refrigerator, sitting right next to the lunch meat!”

Preacher stared at Reedus, then at the micrometer, then back at Gutglor’s moonshine jar. “I put my precision measuring instrument… in the refrigerator?”

“Right between the bologna and the cheese,” Reedus confirmed, trying not to laugh.

“Well,” Preacher said, accepting the cold micrometer with as much dignity as he could muster, “I reckon that explains why I couldn’t find it in the usual places.”

“Don’t feel bad,” Chester said, lighting up his cigarette. “Last month, Gary put his socket set in the parts washer and spent two hours looking for it.”

“That was different,” Gary protested. “I was distracted by that Camaro with the blown head gasket.”

“And now you were distracted by Gutglor’s industrial-strength hospitality,” the Professor observed with academic precision.

“From now on,” Preacher announced, “when I’m working on precision components, I stick to coffee. Just coffee.”

“Probably wise,” Gutglor agreed, though he was clearly pleased that his moonshine had managed to affect even the unflappable Preacher Prechardt. “Matter of fact, this whole incident’s given me inspiration for a new blend. Gonna call it ‘Bearing Grease’ – only 80 proof and guaranteed to keep ya parts slippery, but ya memory dry.”

“Good Lord,” Gary muttered, shaking his head. “You’re gonna name moonshine after what happened to Preacher’s micrometer?”

“It’s a tribute!” Gutglor protested. “Plus, it’s accurate advertising. Bearing Grease keeps things running smooth, and apparently so does my shine – just maybe too smooth.”

“I’ll pass on the Bearing Grease,” Preacher replied, carefully checking his micrometer for accuracy. “This transmission’s complicated enough without adding moonshine-induced confusion to the mix.”

“Your loss,” Gutglor grinned, already planning his next batch. “But I promise to keep it at 80 proof – don’t want nobody else storing precision instruments in the icebox. Matter of fact, I’m also working on a lighter blend called ‘Downshift Drizzle’ – perfect for sipping while you’re working on gear ratios.”

“You got a moonshine for everything, don’t you?” Chester observed.

“Working on it,” Gutglor replied proudly. “Thinking about a whole automotive line – maybe ‘Carburetor Clean’ or ‘Spark Plug Special.’”

The conversation was interrupted by an unusual sight that made everyone stop what they were doing. Axl, the shop dog who usually spent his days sleeping in oil puddles and occasionally barking at backfiring engines, had apparently decided to become a quality control inspector.

The blue nose pittbull was methodically going around Preacher’s transmission workstation, sniffing each organized container of bolts and parts with the interest of a customs agent looking for contraband. But that wasn’t the unusual part – the unusual part was that after each sniff, Axl would sit down, cock his head to one side, and appear to nod or shake his head as if rendering judgment on each component.

“Well, I’ll be damned,” Preacher muttered, watching Axl reject a container of used washers with what appeared to be a disappointed head shake, then approve a box of new synchronizer rings with an enthusiastic tail wag.

“Axl’s got good taste in parts,” Reedus observed. “He just rejected all the worn-out stuff and approved the new components.”

“Dogs can’t inspect transmission parts,” the Professor stated with scientific certainty.

As if to prove him wrong, Axl approached the Professor’s notebook, sniffed it carefully, then sat down and tilted his head with an expression that clearly suggested the calculations might need double-checking.

“Did that dog just question my math?” the Professor asked, incredulous.

“Looks like it,” Gary grinned. “And knowing your track record with practical applications, he might have a point.”

Axl completed his inspection tour by approaching the rebuilt Rock Crusher transmission, giving it a thorough sniff, and then sitting down with what could only be described as a satisfied expression. He looked up at Preacher and gave a single, authoritative bark.

“Well,” Preacher said, scratching his head, “I’ve been rebuilding transmissions for thirty years, but that’s the first time I ever had a dog give me quality assurance approval.”

“Axl’s got standards,” Gutglor explained. “He once spent an hour staring at a carburetor I rebuilt until I realized I’d installed the float upside down.”

“The dog spotted a carburetor problem?” Preacher asked.

“Best diagnostic nose in all of Buzzard Roost,” Gary confirmed. “Though we’re still not sure if he’s actually checking the work or just likes the smell of fresh gear oil.”

“You know,” Chester observed one afternoon, watching Preacher carefully measure bearing clearances with a micrometer, “I been working on cars for twenty years, but I never really understood what was happening inside a transmission.”

“Most folks don’t,” Preacher replied, making a note in his rebuild log. “They just know you push the clutch and move the shifter. But there’s a whole mechanical symphony happening in here – gears meshing, synchronizers matching speeds, bearings supporting loads. It’s beautiful when it works right.”

Gutglor had taken to bringing Preacher samples of his various moonshine flavors, partly out of Southern hospitality and partly to see if alcohol would affect the precision of transmission work. (It didn’t – Preacher had the constitution of a man who’d been dealing with gear oil fumes for decades.)

“This here’s my special batch,” Gutglor announced, offering Preacher a mason jar filled with clear liquid. “Call it ‘Smooth Shift’ – guaranteed to make everything run smoother.”

“I appreciate the gesture,” Preacher replied diplomatically, “but I don’t drink when I’m working on transmissions. Need steady hands for this kind of precision work.”

“More for me then,” Gutglor grinned, taking a swig that would’ve knocked a lesser man unconscious. “Y’all sure do take this transmission work serious.”

“Has to be serious,” Preacher explained, carefully installing a new synchronizer ring. “One mistake here, and the whole thing comes apart again. Better to do it right the first time.”

Intermission: “Now I need to interrupt this tale to remind y’all that when a man treats transmission work like a religious experience, you’re witnessing either the highest form of mechanical craftsmanship or an unhealthy obsession with gear oil – and with Preacher, it was definitely the former.”

After three weeks of meticulous work, the Rock Crusher was finally ready for its resurrection. Every component had been inspected, measured, and either restored or replaced. The case had been welded and machined, new bearings had been installed, and all the gears had been carefully timed and assembled.

“Moment of truth,” Preacher announced, filling the transmission with fresh gear oil. “If I did everything right, she should shift like butter and hold up to whatever that 454 can throw at her.”

The installation process was almost ceremonial. Preacher guided the rebuilt transmission into place with the reverence of a man installing a mechanical heart. Every bolt was torqued to specification, every connection was double-checked, and every adjustment was verified.

“Fire her up,” Preacher said, stepping back from the Chevelle.

Chester turned the key, and the 454 big block roared to life with a sound that could wake the dead and probably did. The engine settled into a smooth idle that suggested serious power lurking beneath the hood.

“Now comes the real test,” Preacher said, climbing behind the wheel. “Let’s see if she shifts.”

He pressed the clutch, moved the shifter into first gear, and slowly let out the clutch. The Chevelle eased forward with the smooth confidence of a car that knew what it was supposed to do.

“First gear, smooth as silk,” Preacher announced, shifting into second. “Second gear, perfect synchronization.”

He worked through all four gears, and the transmission performed like a mechanical symphony – each shift crisp and precise, each gear engaging with the authority of properly matched components.

“Boys,” Preacher said, climbing out of the Chevelle with a satisfied smile, “that there is how a Rock Crusher is supposed to work.”

The assembled Mad Mechanics crew erupted in applause that could’ve been heard in Allsboro. They’d just witnessed the resurrection of a piece of automotive history, and it had been beautiful.

“Preacher,” Chester said, extending his hand, “that was some fine work. You ever want to make this arrangement permanent, we’d be honored to have you as part of the team.”

“Been thinking the same thing,” Preacher replied, shaking Chester’s hand. “Y’all got something special here – good people, honest work, and the kind of problems that keep life interesting.”

“What you think, boys?” Chester asked, turning to the crew. “Should we make Preacher an official member of Mad Mechanics?”

“Hell yes!” Gary declared, lighting up a celebratory Buzzard Dust. “We need somebody around here who actually knows what he’s doing!”

“I second that motion,” the Professor added. “His technical expertise would be invaluable for future projects.”

“Long as he can handle the puns,” Reedus grinned, “I think he’ll shift right into our operation! We’re really gonna be in high gear now!”

“And he appreciates quality moonshine,” Gutglor added, raising his mason jar in salute.

Preacher looked around at the assembled crew – Chester with his cigarette and permanent grease stains, Gary with his chain-smoking habit and practical wisdom, the Professor with his notebooks and scientific approach, Reedus with his endless puns and creative chaos, and Gutglor with his moonshine and mysterious mechanical instincts.

“You know what?” Preacher said, a slow smile spreading across his face. “I’ll do y’all’s transmission work but I gotta run my daddy’s shop too. How does part time sound?”

And so Samuel “Preacher” Prechardt became the part-time transmission specialist for the Mad Mechanics crew, bringing with him decades of transmission expertise, a methodical approach to impossible problems, and the kind of mechanical precision that would keep their wildest projects running smoothly when the job called for his particular skills.

As the sun set behind the pine trees and the radio crackled to life with Luke Combs singing “Beer Never Broke My Heart,” another chapter in the Mad Mechanics saga began, enhanced by a partnership with a man who could make any transmission sing hymns and purr like a contented church cat.

“Boys,” Chester announced, lighting up his Camel Non-Filter, “I do believe we just got ourselves a real professional.”

“Speak for yourself,” Gary replied, but he was grinning despite himself.

“Just promise me one thing, Preacher,” Reedus called out. “Don’t try to bring too much sanity to this operation. We got a reputation to maintain!”

“Wouldn’t dream of it,” Preacher replied, already planning the next impossible restoration project in his head.

Outro: “Now that there, folks, is what I call a genuine meeting of the minds. Sometimes the best additions to a team are the ones who bring skills you didn’t know you needed, and the wisdom to know when to be precise and when to let creativity run wild. And if you ever find yourself needing a Rock Crusher rebuilt by someone who treats transmissions like sacred relics, well, you know where to find Samuel “Preacher” Prechardt and the boys at Mad Mechanics.”

Leave a reply to spwilcen Cancel reply